What is PUSH?

Instead of building reservoirs, PUSH facilities repurpose abandoned flooded mine shafts as large-scale energy storage systems. Each facility works like a giant rechargeable battery. When there is excess electricity available, water is pumped up from in the mine allowing it to ‘charge’. When more electricity is needed, the water is released back downward through turbines, generating power. This is known as ‘discharging’.

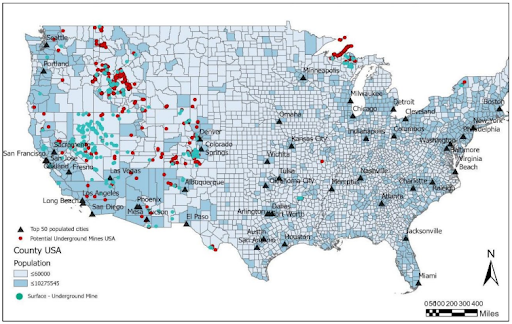

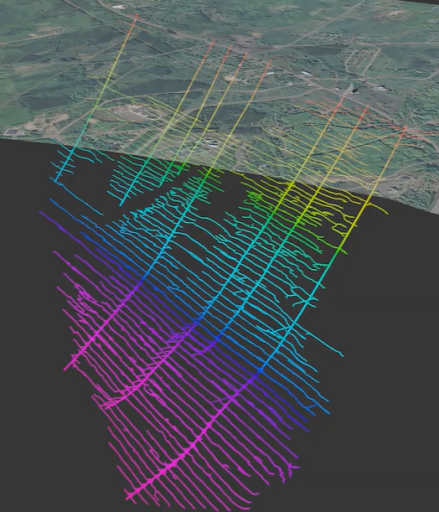

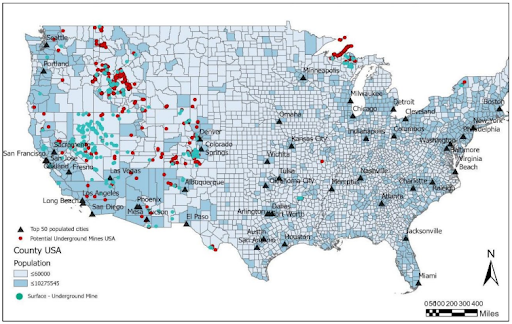

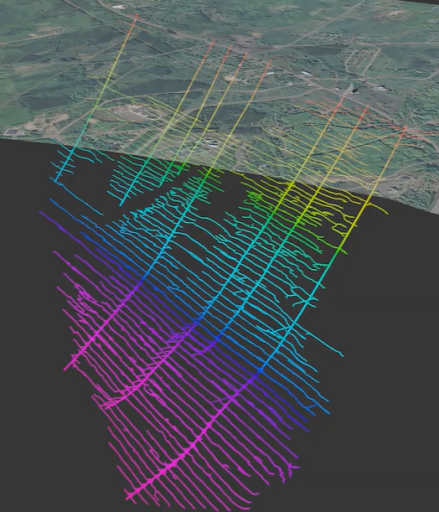

Research by the Keweenaw Energy Transition Lab (KETL) has identified a total of 968 U.S mines as feasible mines for PUSH facilities. The Keweenaw, once known for its copper mining heritage, is home to several of these sites, with Marquette County holding the most here in Michigan. This positions the Upper Peninsula to transform its mining legacy into a foundation for clean energy assets and allows for the possibility to meet rising demand for large-scale energy storage as renewable power expands.

Project History

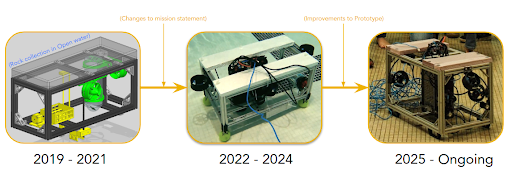

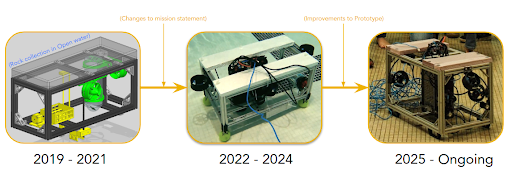

The DIVER project was originally involved in designing a low-depth AUV that could collect rock samples for scientific research in an open-water environment such as the Portage Canal. However, after being inspired by the PUSH facility research done by Professors Timothy Scarlett and Roman Sidortsov, both of which are actively involved with the Keweenaw Energy Transition Lab (KETL) here at Tech. We began transitioning our design towards developing an ROV/AUV capable of operating within an enclosed environment. Now, with the mentorship of our advisor Dr.Paul van Susante, the team continues to strengthen its approach towards project design and development.

Our Project

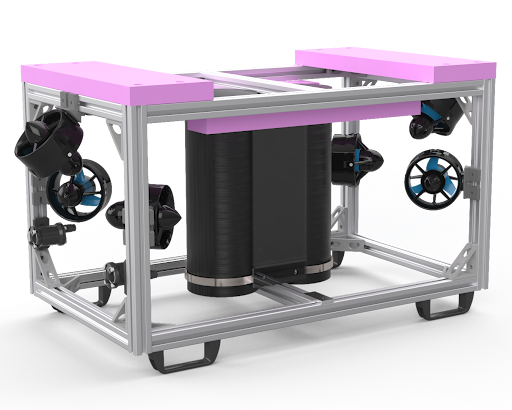

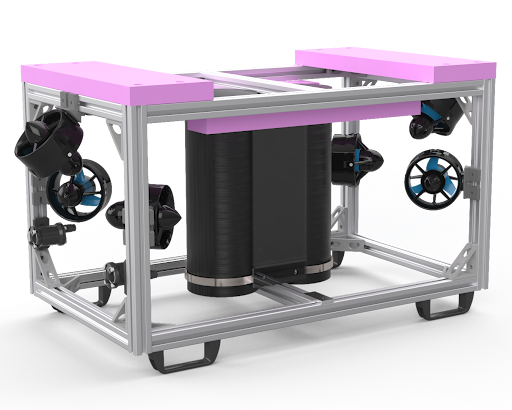

This project centers on the design of a robust, deep-diving robotic system intended for conditions more unforgiving than outer space. Flooded mine shafts impose immense external pressures, eliminating communication links and offer no possibility of recovery in the event of failure. Thermal gradients at depth create unpredictable currents that disrupt navigation, while the absence of GPS requires precise environment localization. Meeting these demands encourages substantial onboard computer capacity, which in turn increases the ROV/AUVs size, weight, power consumption and heat generation. Addressing these constraints represents the central focus of our team’s efforts as we work on our project.

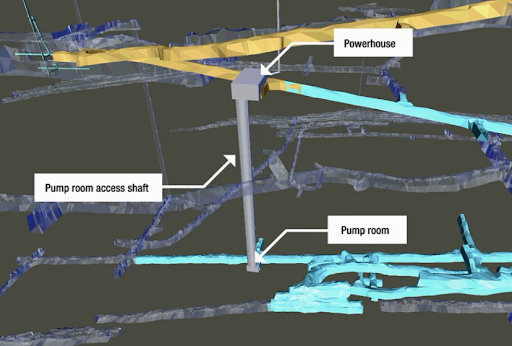

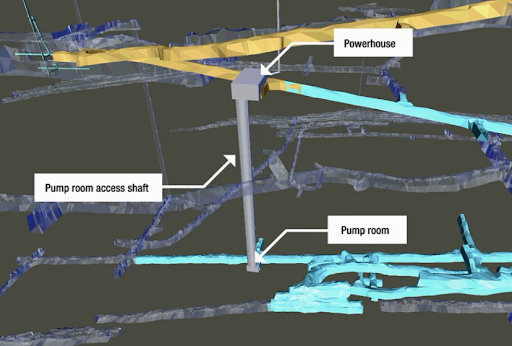

This also includes finding potential testing sites for our project. As seen above, the local Quincy Mine was chosen to be the best candidate. As it was at one point the deepest mine in the area, with well mapped and documented files compared to other nearby mines. The depth of the deepest areas are found to be 9,260 ft deep, while other areas are left to be 6,200 ft deep. This leaves our team with a unique challenge to solve as we push the limits of robotics to support future clean energy solutions in an unforgiving environment.

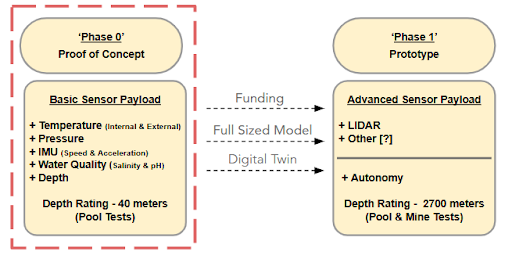

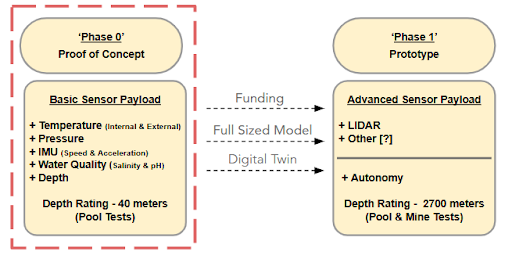

The DIVER project is structured into two phases: Phase 0, and Phase 1. Phase 0 serves as a proof of concept, where a ROV is built to be capable of doing basic data collection and analysis, which shows people, organizations, or other companies the fundamental feasibility of a design application that could navigate in an enclosed environment. Phase 1 begins after we find funding for the project which can support a bigger and larger build of an AUV design. This phase will allow the beginning of exploring the Quincy mine. Which will include additional sensors to the payload already existing on the previous platform, lidar mapping, autonomy, and further improvements. As of 2025, our project is working on Phase 0.

Mechanical

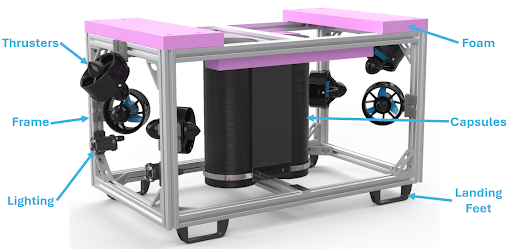

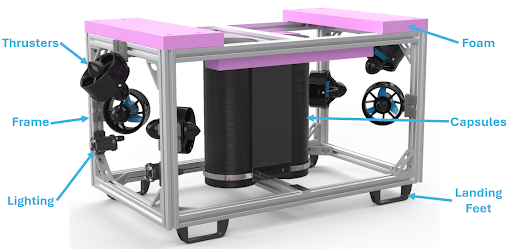

The mechanical sub-team designs the hardware of the ROV/AUV, following system and design engineering practices to create a reliable platform to use in future iterations. This process begins with extensive research as ROV/AUV navigation in confined spaces is not widely studied. Afterwhich, the requirements, constraints and objectives of our design is set. This allows for decision making to take place, where we then start our design process towards modeling in Solidworks CAD to develop critical components for our ROV/AUV. Usage of Finite Element Analysis (FEA) allows our team to evaluate the structure integrity, select appropriate materials, optimize Safety of Factor (SOF), and verify that the ROV/AUV can withstand the pressure that it would be exposed to. Design and testing in the SDC pool marks the final step before the process loops back, ensuring each iteration of the ROV/AUV design is continuously improved upon.

Controls

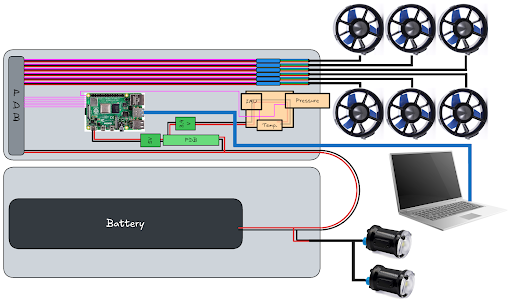

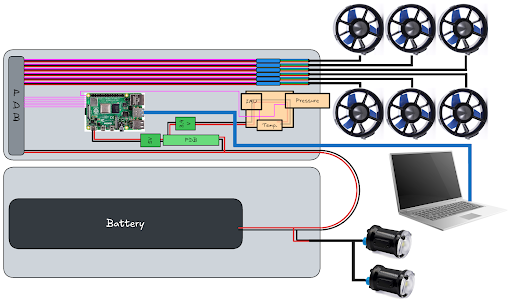

The controls subteam works to make sure that the frame designed and built by the mechanical team will move and process its surrounding environment. The subteam consists of two main divisions: electrical and software. The electrical division works with integrating sensors, thrusters, and other hardware components into a centralized system called the Power Distribution Board (PDB). Once plugged into a battery, the PDB then regulates and supplies each component with power which ensures functionality through all major systems for the vehicle. The software division develops logic and control algorithms that allow the ROV/AUV to sense its environment and respond to operator inputs. For example, a programmed control that translates to a computer command such that pushing the up arrow equates to upward movement. Communication between the ROV/AUVs onboard sensors and the main computer is another responsibility for the software division. Ensuring that real-time data are accurately displayed. Together, both divisions transform the empty frame of the ROV/AUV to a responsive vehicle with ‘intelligent’ capabilities.

Pool Test

Pool tests are the next step in ROV/AUV development. These tests take place in the Student Development Complex (SDC). During these tests, the team assesses core functionality of the design, evaluation of the vehicles systems, and verification. By running pool tests, the team can identify potential problems or design flaws which provide feedback for refining system performance and improve reliability in future tests.