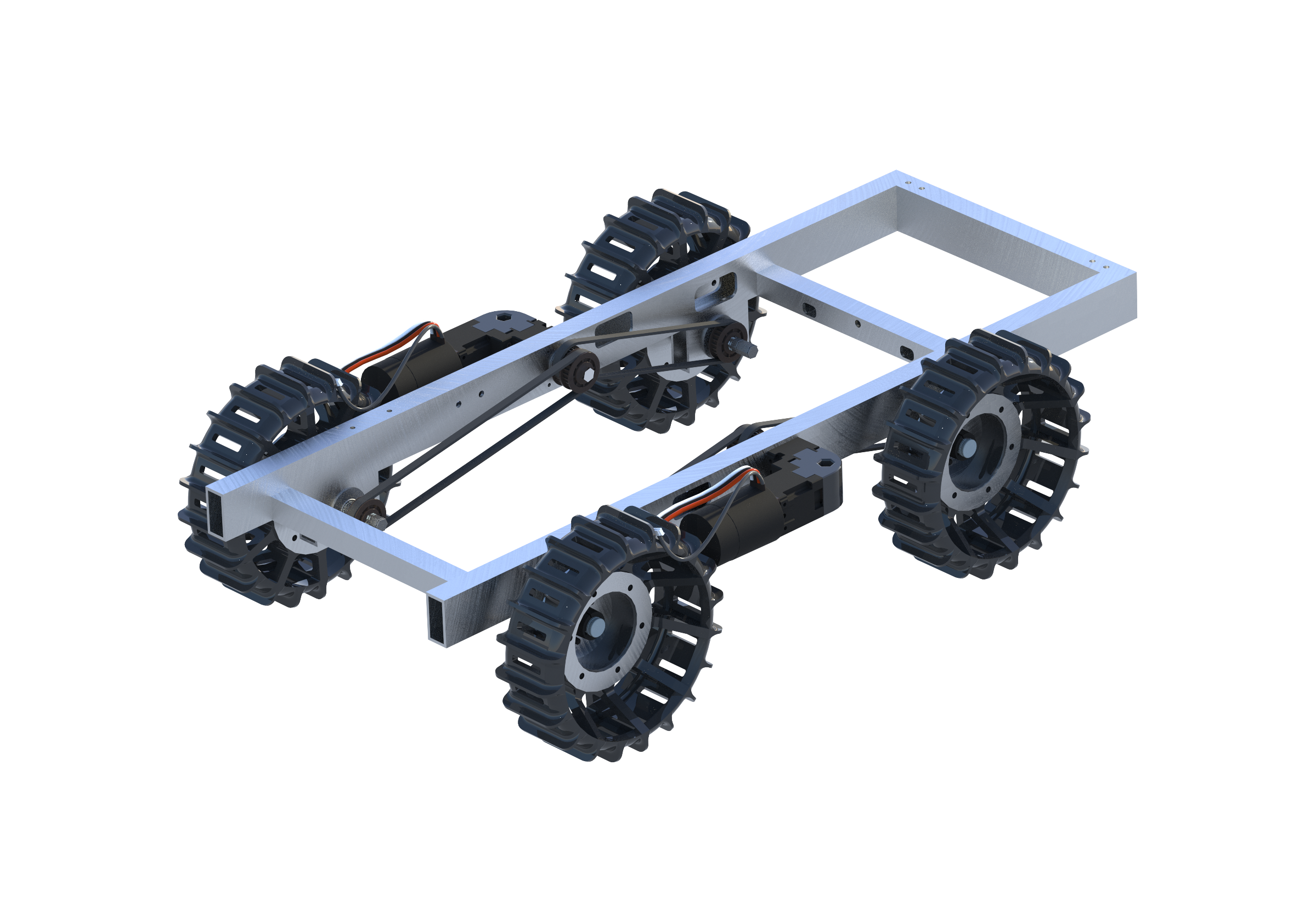

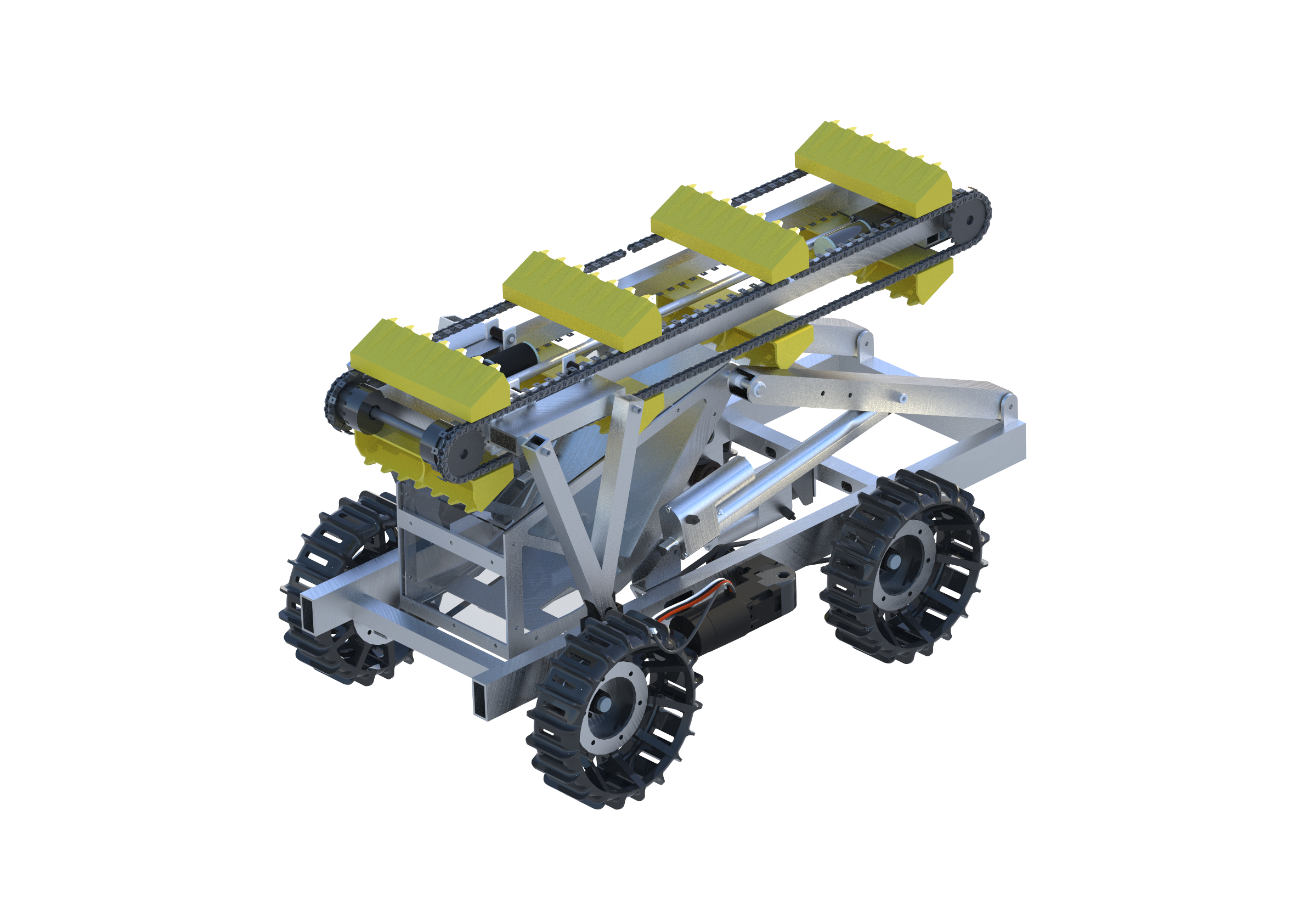

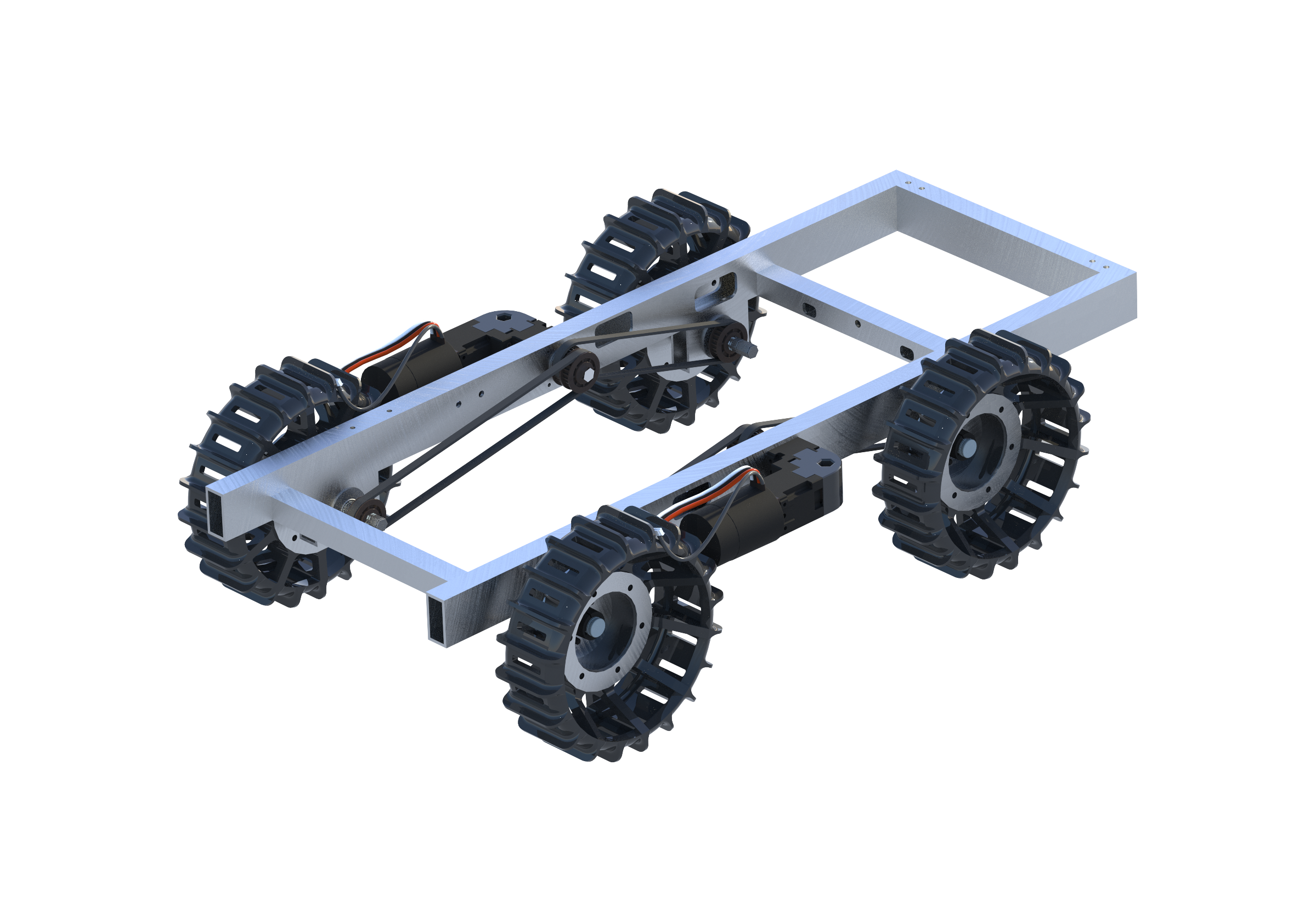

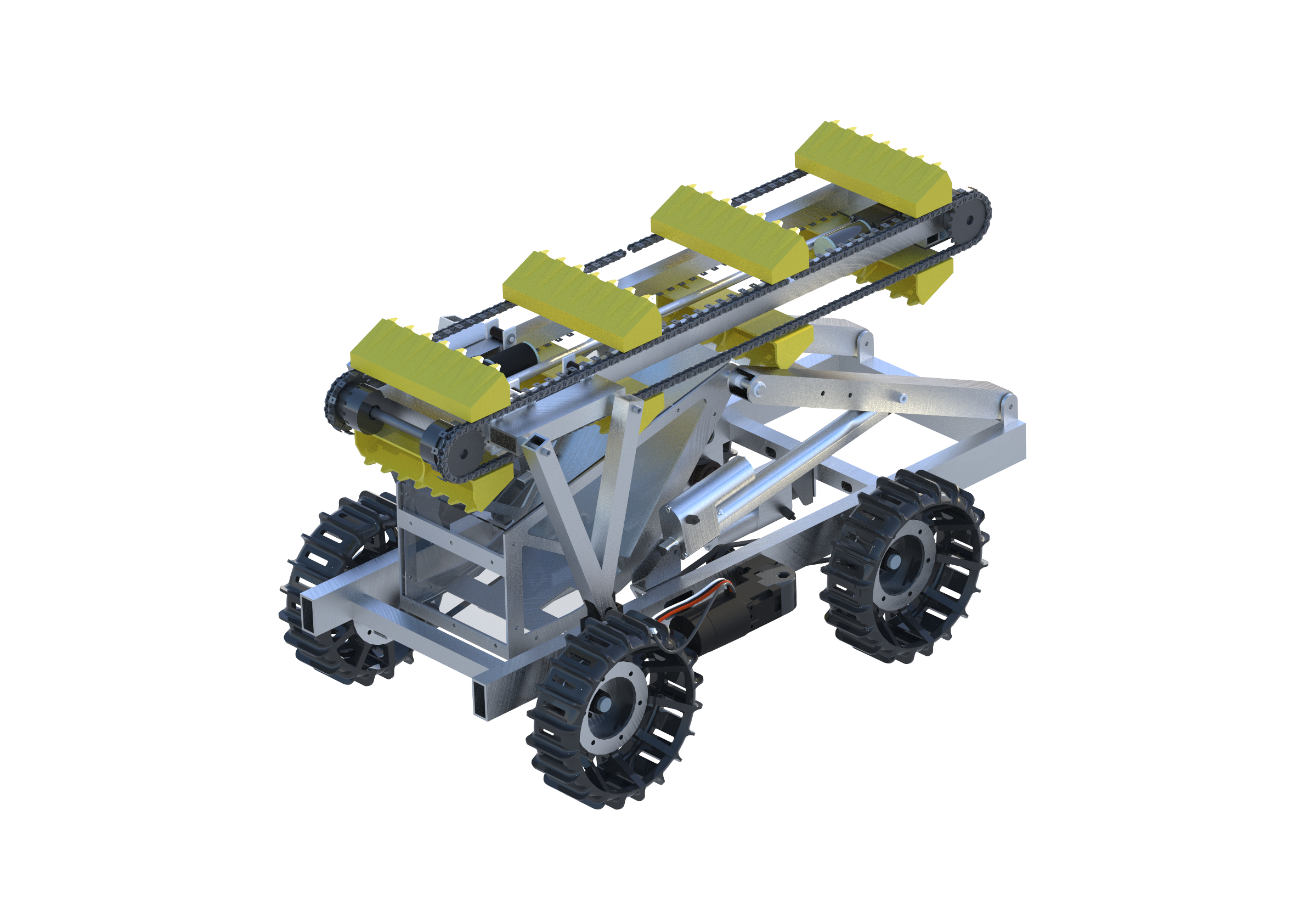

The Chassis & Mobility Subsystem (CAM)

The Chassis & Drivetrain is in charge of

the design, manufacturing, and testing of the lunabotcs

chassis and drive train. We make sure that these two parts

of the rover fit within competition constraints as

requirements made by our team, that our designs are viable

as well as optimal for the competition and our CAD is up to

date and accurately represents what we have manufactured.

We use a combination of CAD and FEA to create a chassis that

fits our needs while also reducing the weight of the design

by removing unneeded material found in our FEA analysis. Our

drivetrain system is designed to reduce the number of motors

needed to drive the rover white being able to fit in the

limited build volume of the competition. Lastly, our wheels

are 3D printed to reduce weight but are designed optimally

to the extent that they can withstand 250lb of compressive

force. We are constantly looking for ways to reduce weight

while improving our structural integrity.

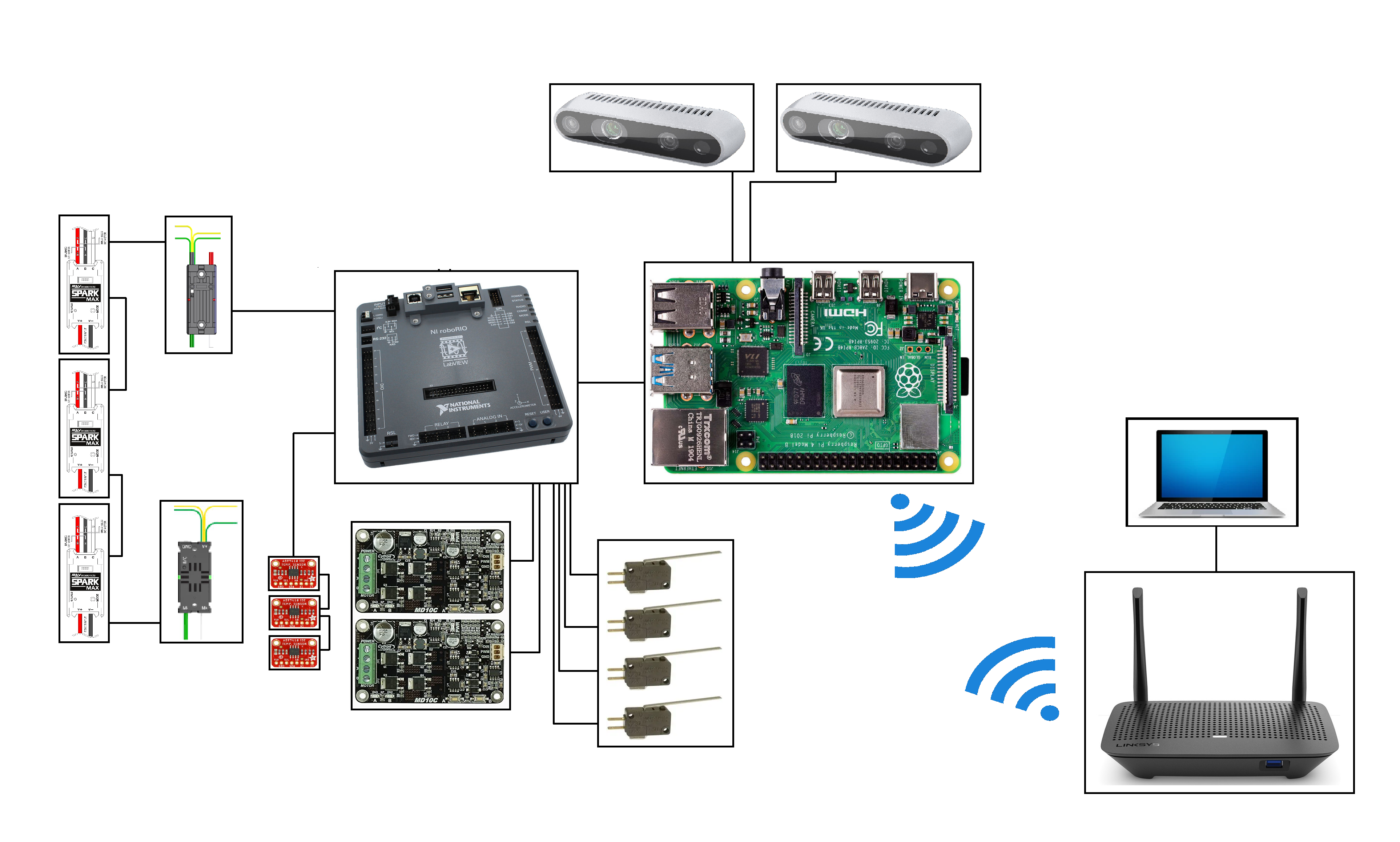

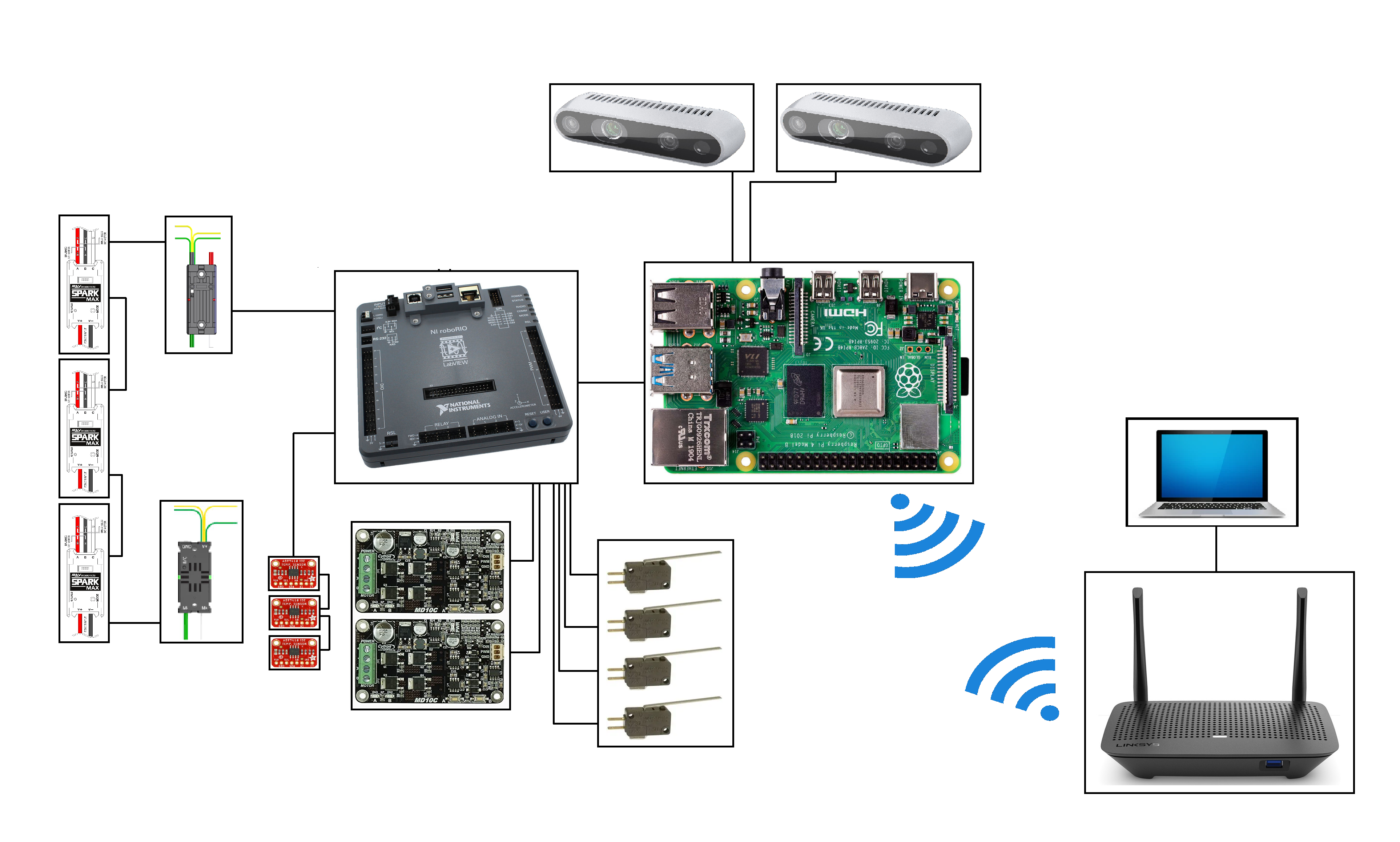

The Electrical Hardware & Data Acquisition Subsystem (EDAQ)

Our team is responsible for the coordination

and management of all the electrical devices and wiring on

the robot. We ensure that all crucial components such as the

drivetrain, excavation motors, hopper conveyor, and

actuation system are secured and receive the enough power

from the battery to operate at their optimal capacity. All

components are also linked together via communication wires

which will transfer sensor information to the brain of the

robot, the RoboRIO, and allow the Software and Communication

team to control the robot quickly and reliably in both

manual and autonomous mode. Every step is done properly and

multiple safety measures have been taken to protect both the

users and the robot from itself while in operation.

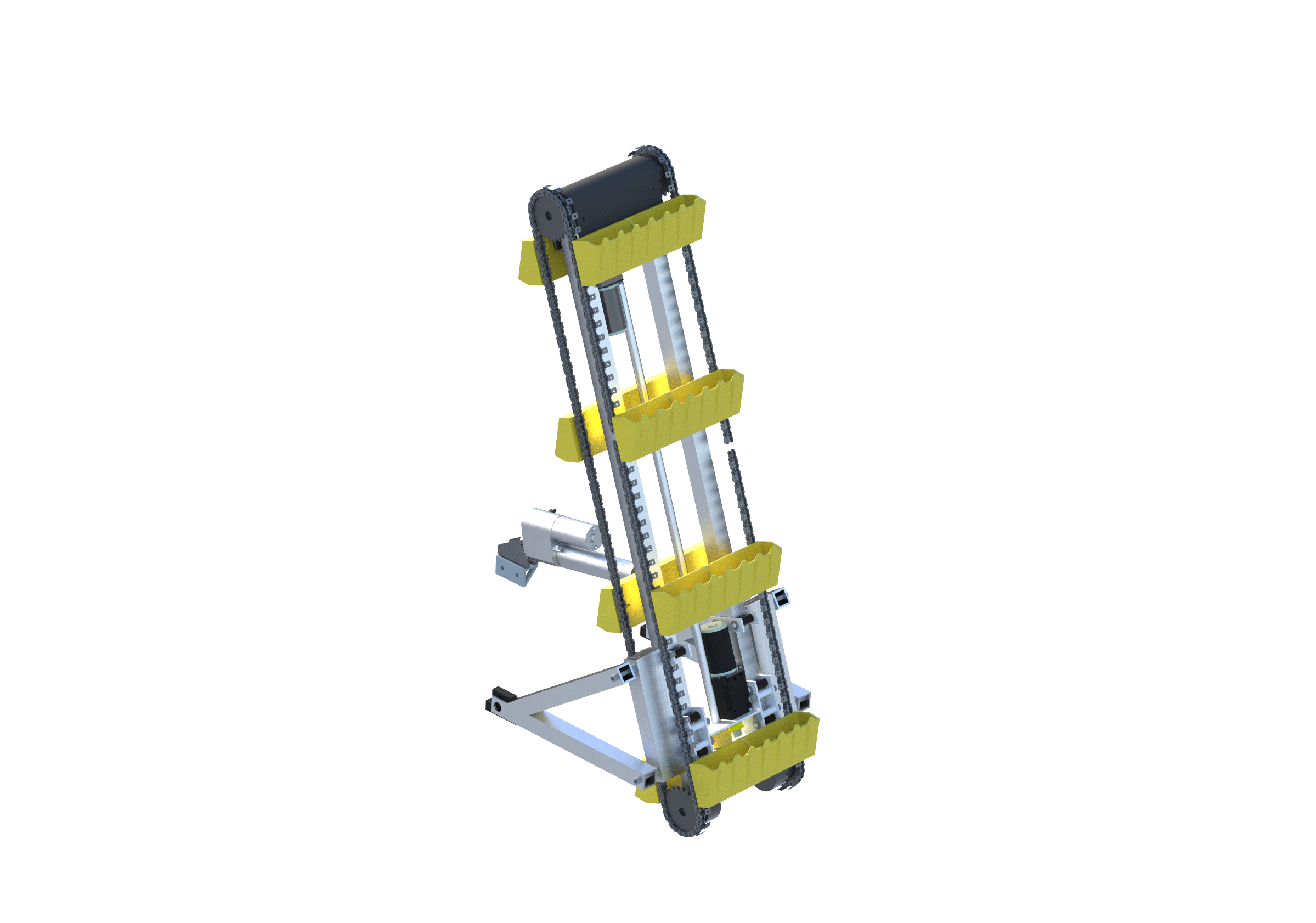

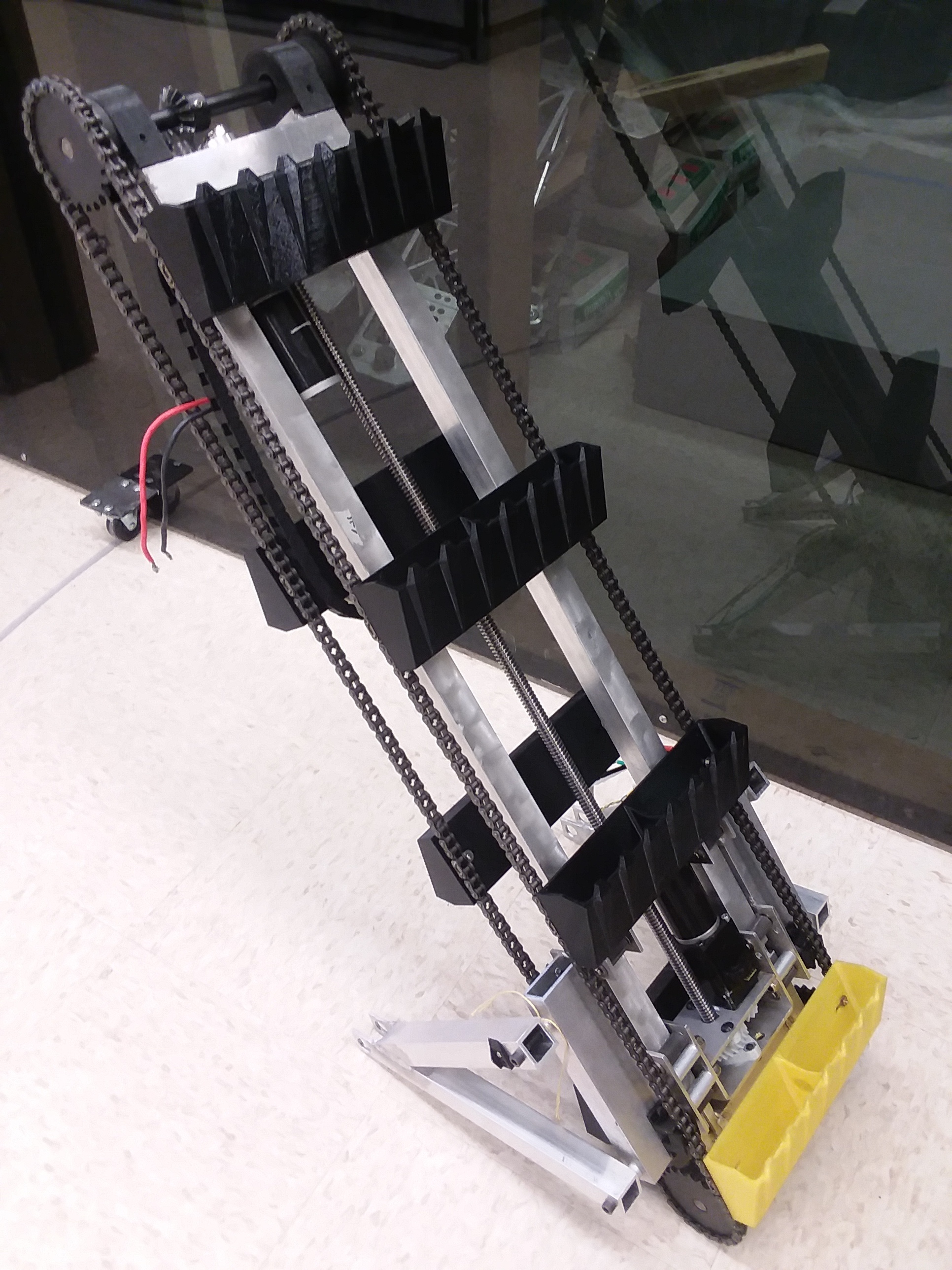

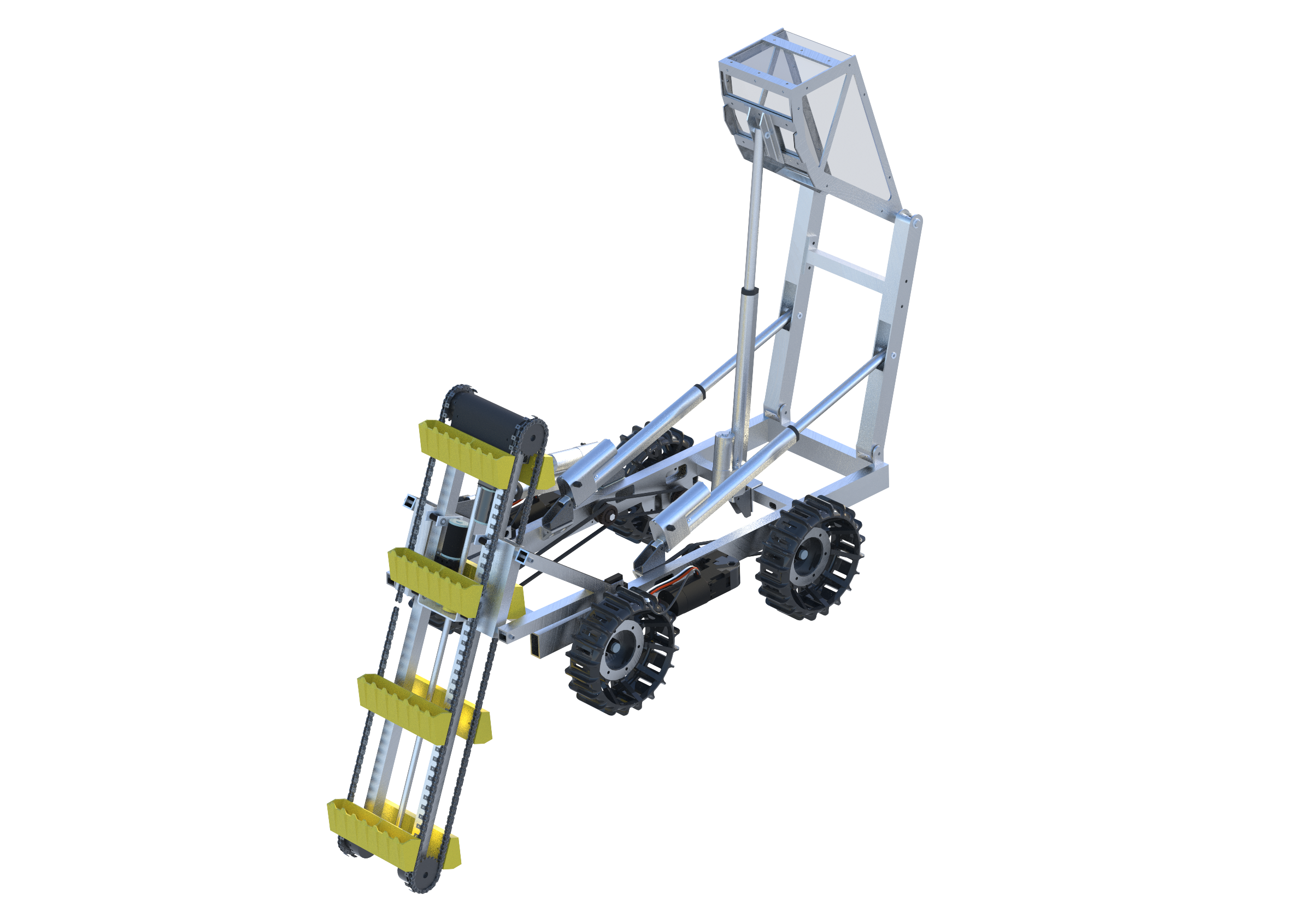

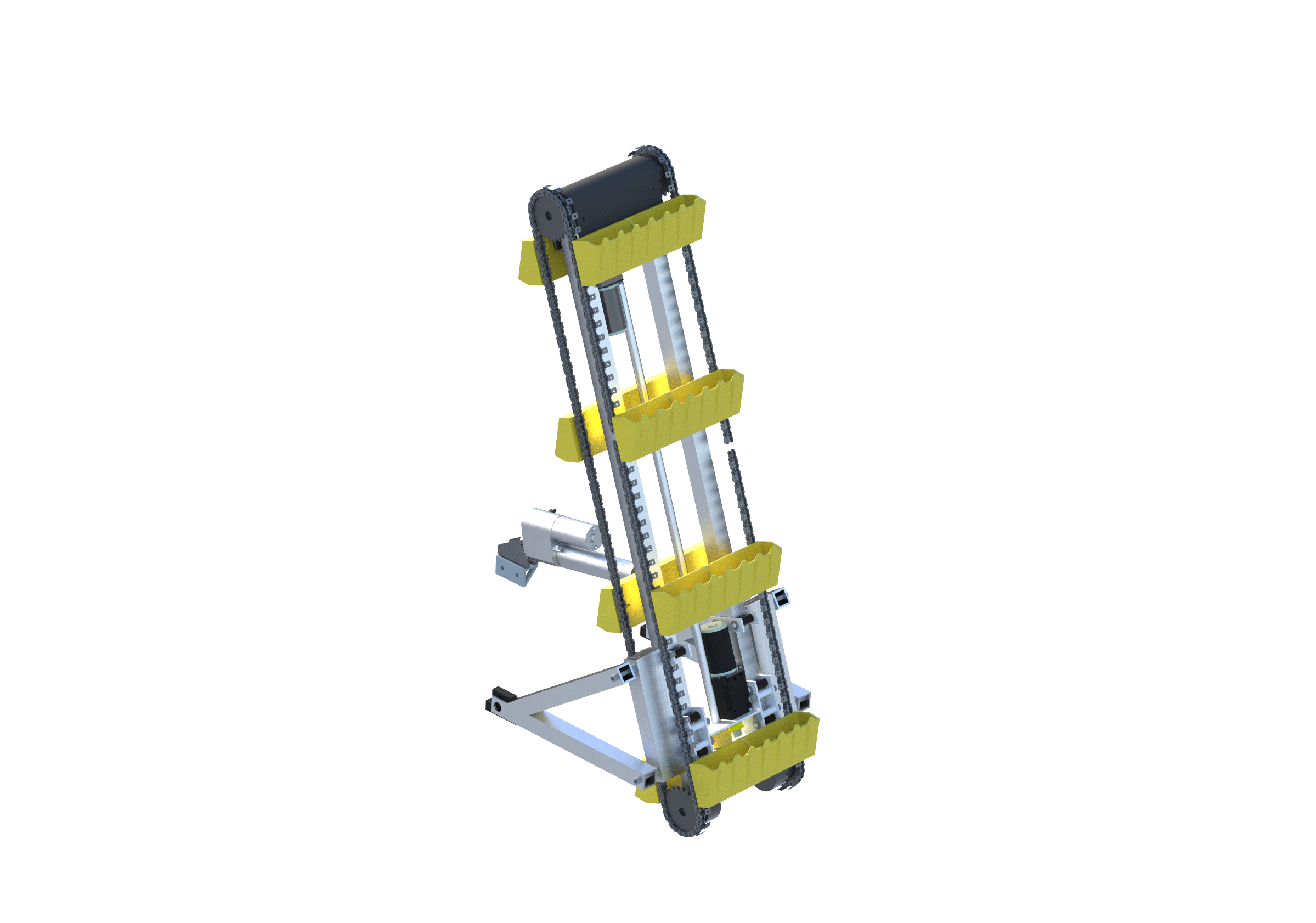

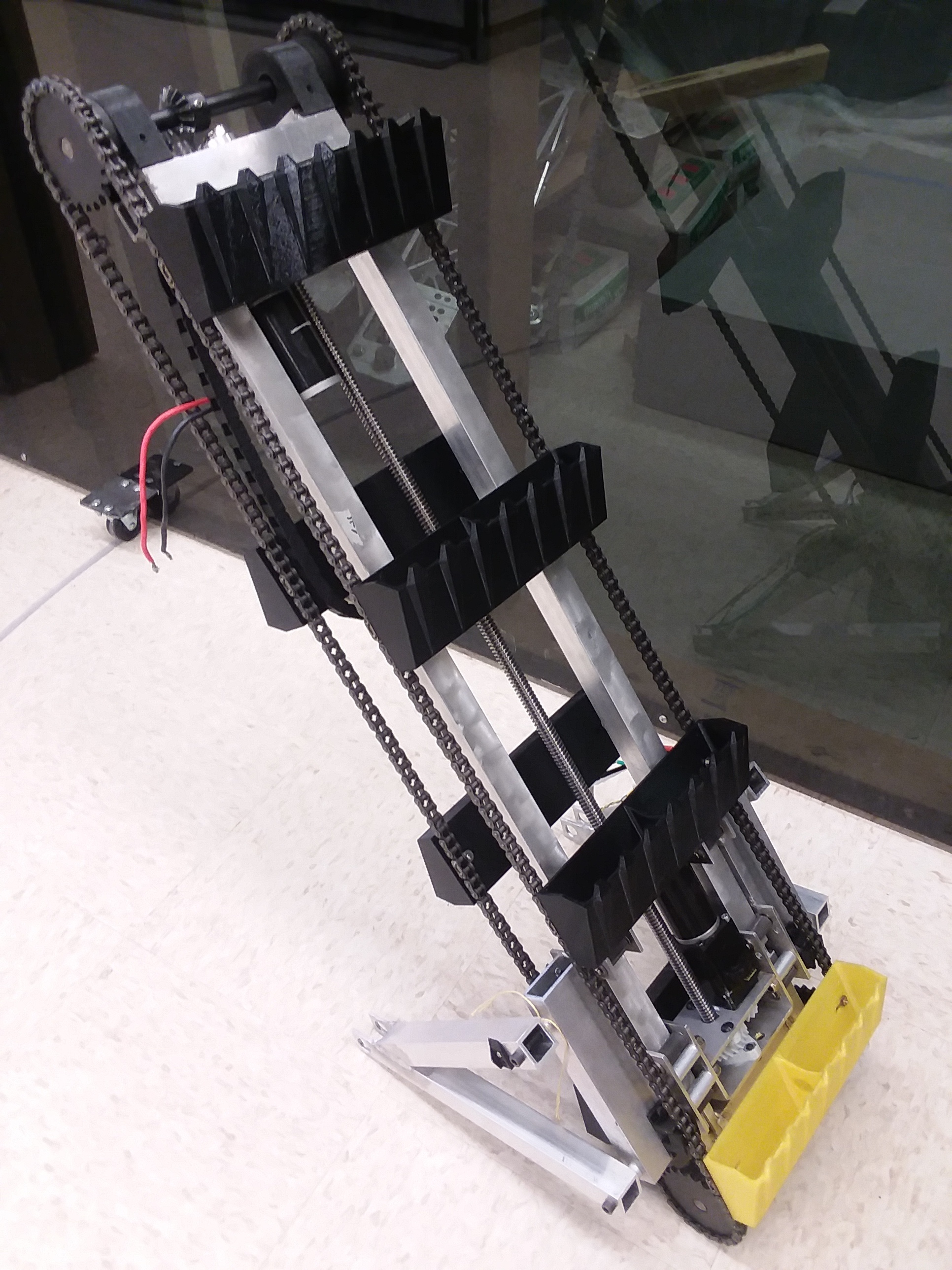

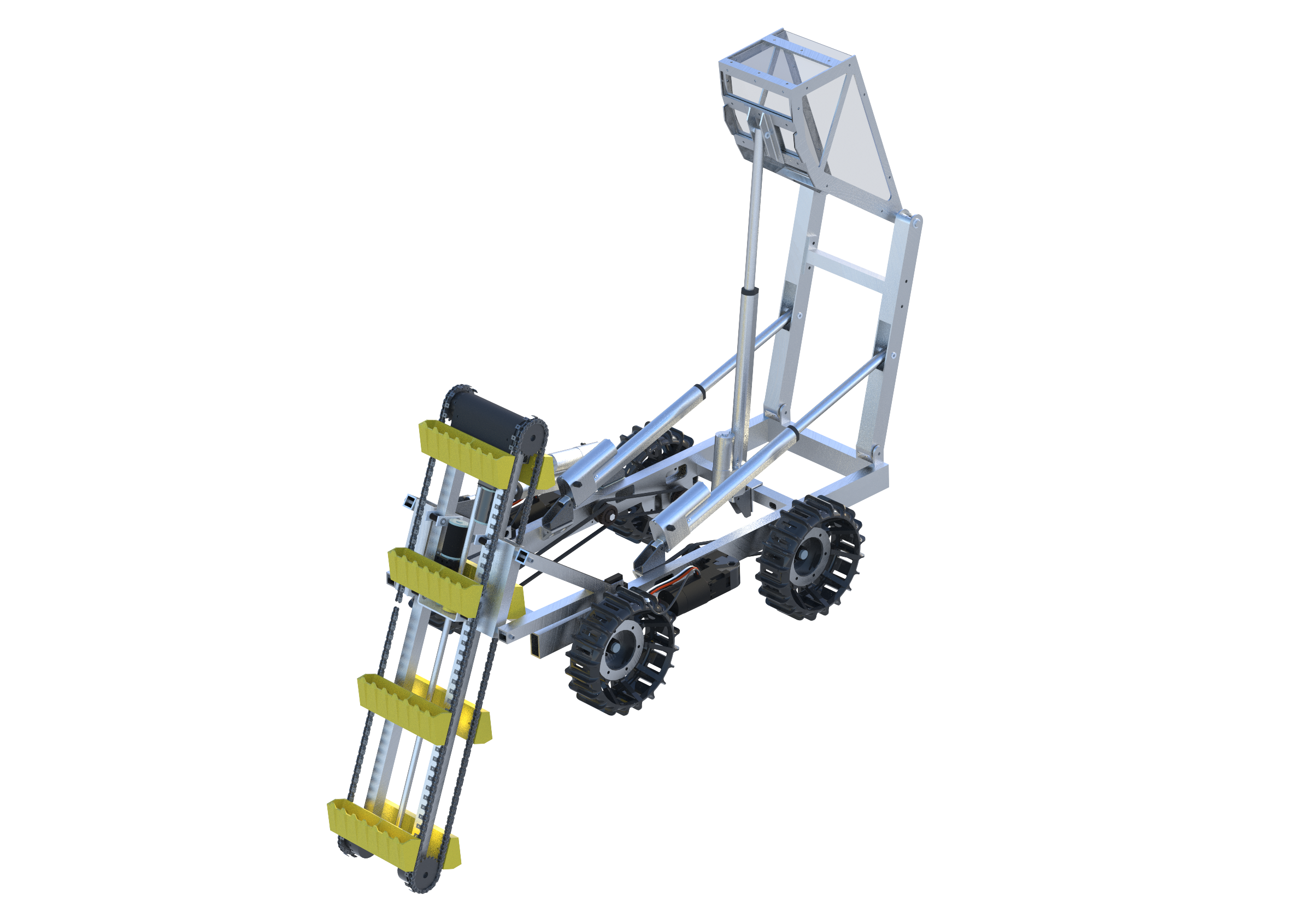

The Excavation Subsystem (EXC)

The Excavation sub-team handles the

design, optimization, construction, and testing of the

excavator for the Lunabotics robot. We make sure that our

system is able to mine the required amount of rocks and

regolith for the competition. The design of our system is

very compact and has several intricate mechanisms that work

together to activate, extend, and excavate material. Due to

the size constraints given by the rules, our robot must

start off in a compact form. The excavator starts off folded

up on top of the hopper and hopper conveyor. The arms the

excavator is attached to are able to pivot on bearings,

which allow the excavator to fold down into its active

position.

Our excavator uses a bucket ladder design with

eight buckets attached to a chain that is driven by a motor.

The buckets rotate around the frame on the chain. When the

bucket takes a scoop of material, it brings it up to the top

of the excavator and then dumps it into the hopper which is

positioned to catch the incoming rocks and regolith. In

order for the excavator to mine down deep enough to reach

the desired rocks, the excavator needs to be able to extend.

This extension is achieved by the use of an ACME rod and

nut. The carriage of the excavator houses a motor and

gearbox that drive a set of gears that rotate an ACME nut

around the acme rod. This nut is held in place by two thrust

bearings. The rotation of this nut facilitates the extension

of the excavator into the ground. When the excavator digs as

far as it can, it then uses the same mechanism to bring it

back to its ready position.

The Hopper & Material Handling Subsystem (HOP)

The Hopper and Material Handling sub-team

is in charge of designing the mechanisms to handle the

excavated material during transportation and deposit it at

the collection point, which is a sieve located on a wall of

the arena. We designed the Hopper System to be a single bucket

that can hold an entire kilogram of gravel in 1 duty cycle

of the robot and can deposit it through the use of 4-bar

linkages. To validate that the bucket frame, drive links,

and attachment points will not fail under competition loads

we conducted a comprehensive Finite Element Analysis on the

system. The results of our FEA allowed us to proceed further

with the linkage design. To off-load the material excavated,

the 2 linear actuators located on the frame of the robot

will extend lifting up the bucket in the air then the center

linear actuator will extend to tip the bucket. The final

details of our design are currently being worked out and the

manufacturing will begin shortly.

The Rover Autonomy & Networking Subsystem (RAN)

The Software & Communication Team was

created to have two major Spheres of influence on the

Lunabotics project, which, as the name suggests, are writing

Software for the Robot and controlling Communications

throughout the Control system. The Former Sphere involves

writing programs to control various actions around the robot

using, preferably, closed-loop methods such as extending the

excavator into the ground based on the input of an encoder

and limit switches. This is done primarily through the use

of the programming environment used in FRC, made by National

Instruments, and known as "LabVIEW." Other Programming

languages such as Python, C, and HTML are used for various

other portions. You can thank us for this lovely website.

When it comes to the competition, our subteam is the most

crucial, as the majority of points won during the 15 minutes

of operation are achieved through the use of automation.

The latter sphere of influence, the Communications aspect,

is achieved through the utilization of various electrical

components and programming methods such as a Raspberry Pi,

Wireless Access Point, and RoboRIO. This combination of

devices, languages, and connections makes communications one

of the more complex portions of the subteam and an ongoing

project to find the best way to send data to and from the

robot.

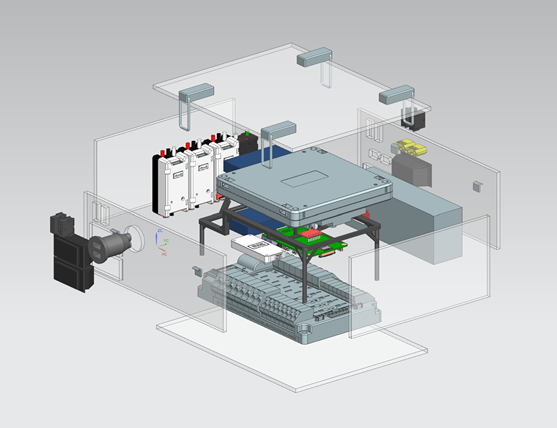

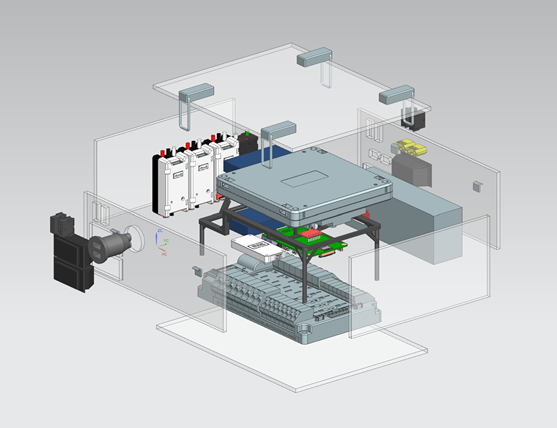

The System Integration Sub-Team (SYS)

The System Integration sub team handles

the system wide CAD model. Each sub team is in control of

their respective sub models. System integration assembles

all of the sub systems into the full assembly. System

Integration also has a system of approving new changes to

any sub system. When a sub system makes a change, they fill

out a google sheet with the change they made and a path to

the file they want updated. System integration ensures that

the change that was made does not interfere with the rest of

the system, and follows the naming convention. If the file

meets the criteria, the change is accepted and fully added

to the full system. System Integration also keeps track of

the robots mass and overall dimensions to ensure the robot

meets competition requirements. The estimated mass from the

CAD and the dimensions are compared to the as-built systems

to ensure they stay within the requirements. System

Integration also keeps track of system wide and sub system

testing matrices.

Updated: October 11, 2022